Why Choose our Lubricating processing aids ?

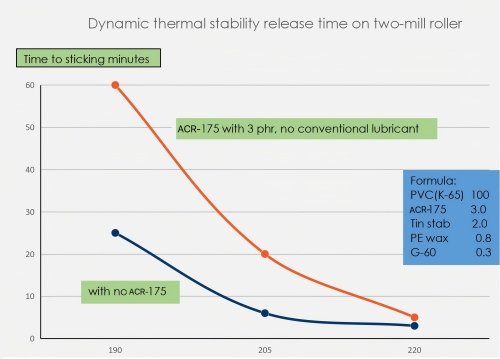

Adding our FINE-ADD series lubricating processing aids helps to reduce friction and lower melt viscosity, ensuring smooth flow during PVC products manufacturing and meanwhile with no migration and precipitation of small molecules On the surface of the product.

It can highly improve the process-ability & fluidity with lower dosage, avoid hot metal surface sticking ,reduce the frequency and time of mold cleaning, prolong the production cycle with higher efficiency.

Also it can largely promote surface glossiness of PVC finished products in diverse plastic formulations without any negative effects on the mechanical properties .

Increase out put rate.